Integrated Business Planning in the Retail Industry

Integrated business planning has evolved in the manufacturing and supply chain industry from its origins of Sales and Operations Planning which was first developed back in the early 1980’s by Walt Goddard and Dick Ling.

The basic principal is that Supply should be driven by the objective of balancing Supply and Demand and not by re-order point and historical data as it traditionally was. Instead the business should be driven by Demand Plans (Sales Forecasts), obviously this also comes with challenges, salespeople and account managers can be optimistic or pessimistic and marketing people can be over enthusiastic about the potential of the next new products or marketing campaigns that they are launching. Most of these things are ‘behavioural’ by assigning accountability to sales and marketing for forecast accuracy and lack of bias in the Demand Plans can address these behaviours. People will behave based upon the way that they are measured and as long as KPIs are used for learning and not blame reasons then improvement is guaranteed. Integrated Business Planning is basically about ensuring that all plans for new product introduction, sales, promotions are tied together in an integrated set of plans that also drive financial projects and decision making. It is important that these plans are presented in both volume and financial terms, but as one set of integrated plans. In this way projections can be compared to annual operating plans (budgets) and gaps identified allowing realistic plans and actions to be put in place to close any gaps in revenue, profit, capacity, capability, product and resources. This is built into a formal monthly process which is continuous but structured through a series of reviews which ensure that those plans are properly executed on a monthly, weekly and daily basis.

See below the latest thinking of that monthly IBP structure.

There is lots of discussion as to whether IBP is a separate process from the day to day supply chain and execution process, however in our view world class companies integrate all plans from strategic to execution.

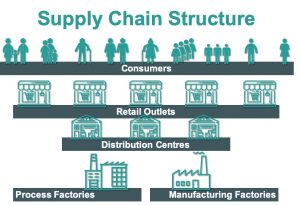

It is our observation that this approach to business integration has yet to be fully adopted in the retail industry. Part of this could be due to systems, however it is more likely that supply chain and inventory management in the retail industry has not had the same focus as brand development and management. However, the challenges for any retail business are the same as any manufacturing company which is the balance of supply and demand. The basics of moving product between nodes in a supply chain is the same whether it is through a manufacturing supply chain or an end to end raw material to customer supply chain. This is only getting more complex as the retail industry enters into ‘omni-channel’ trading and returns become a significant part of the retail supply chain. This must only mean that Integrated Business Planning across the end to end supply chain is more important in today’s environment not less.

We have worked with companies who have applied IBP from clothing, chocolate, watches, food, flowers, drink, tea and coffee, in fact all sectors of the retail industry. In some cases, the retail outlet actually owns the supplier e.g. Morrisons (flowers), Thornton’s (chocolate) and Bettys (tea, coffee and bakery). Based upon the ‘power’ of the major retailers when manufacturers interface with large retailers there is often a high degree of friction; and often ends up disrupting the supply chain through promotions which reduces profits for all parties, it also creates a so called forrester (bullwhip) effect on the supply chain which also does not increase consumer demand but does reduce efficiency, increase costs and reduce profits.

All of this can do nothing but reinforce the need for Integrated Business Planning in the retail industry.

As Linda Kohanov says in her book ‘The Five Roles of a Master Herder’ – “learning to share power (‘integration’) is the challenge of the twenty first century”.

In the situation where a manufacturer is supplying a retailer then the requirement for collaborative planning is essential hence the need for Integrated Business Planning and linked IBP processes throughout the supply chain.

Collaboration has been discussed many times, but collaboration can and will reduce inventory, increase availability and increase sales.

The basic requirements for collaboration are common plans and objectives, trust and transparency which means a change of behaviour and leadership focus.

Dave Manning

DM Integration Ltd

LEADERSHIP t h r o u g h INTEGRATION