DMi White Paper: ERP Implementation Principals Go Live Criteria

Introduction

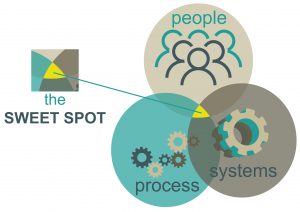

Many organisations decided to implement a new ERP system because the current systems are not integrated, becoming unsupported, lack latest functionality or technology, poorly used (probably not a system issue!) or the belief is that a new system will be the answer to enable the business to achieve world class levels of performance and a competitive edge. The catalyst for the need to upgrade systems may well be any of the above but systems are not ‘the answer’. The answer is to embrace change and transformation by focusing on the ‘sweet spot’ of excellence where systems, process and people are completely integrated.

DMi The Sweet Spot

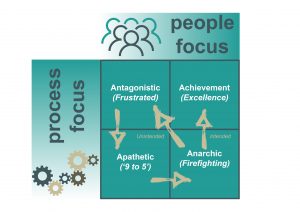

The relationship between people and process/systems was extremely well illustrated by a model that Peter Wickens (HR & IT Director of Nissan Cars in the UK) put forward to describe the business environment that will exist based upon the degree of process and people focus in an organisation.

Based on Peter Wickens’ Original

Most organisations have a high level of ‘fire fighting’ in order to get the job done despite the processes and systems not because of them and rely on ‘good people’, the so called informal company. At some point it is recognised that greater focus on process and systems is required and some sort of ERP project is initiated with the intention of moving from fire fighting to excellence.

Initially it is recognised that this transformation is not only about systems, people must come on the journey and the biggest change required will be cultural and behavioural. However most companies do not put sufficient effort into demonstrated leadership or behaviour change and even if some training takes place to explain how to use the new system, very little education takes place to explain why the change is necessary and what ‘good looks like’. The results are that the processes are not redefined against best practice and rather than the intended move from fire fighting to excellence people move to frustrated. People will not stay frustrated for long and will quickly move back to nine to five, which is where the organisation started several million dollars ago!

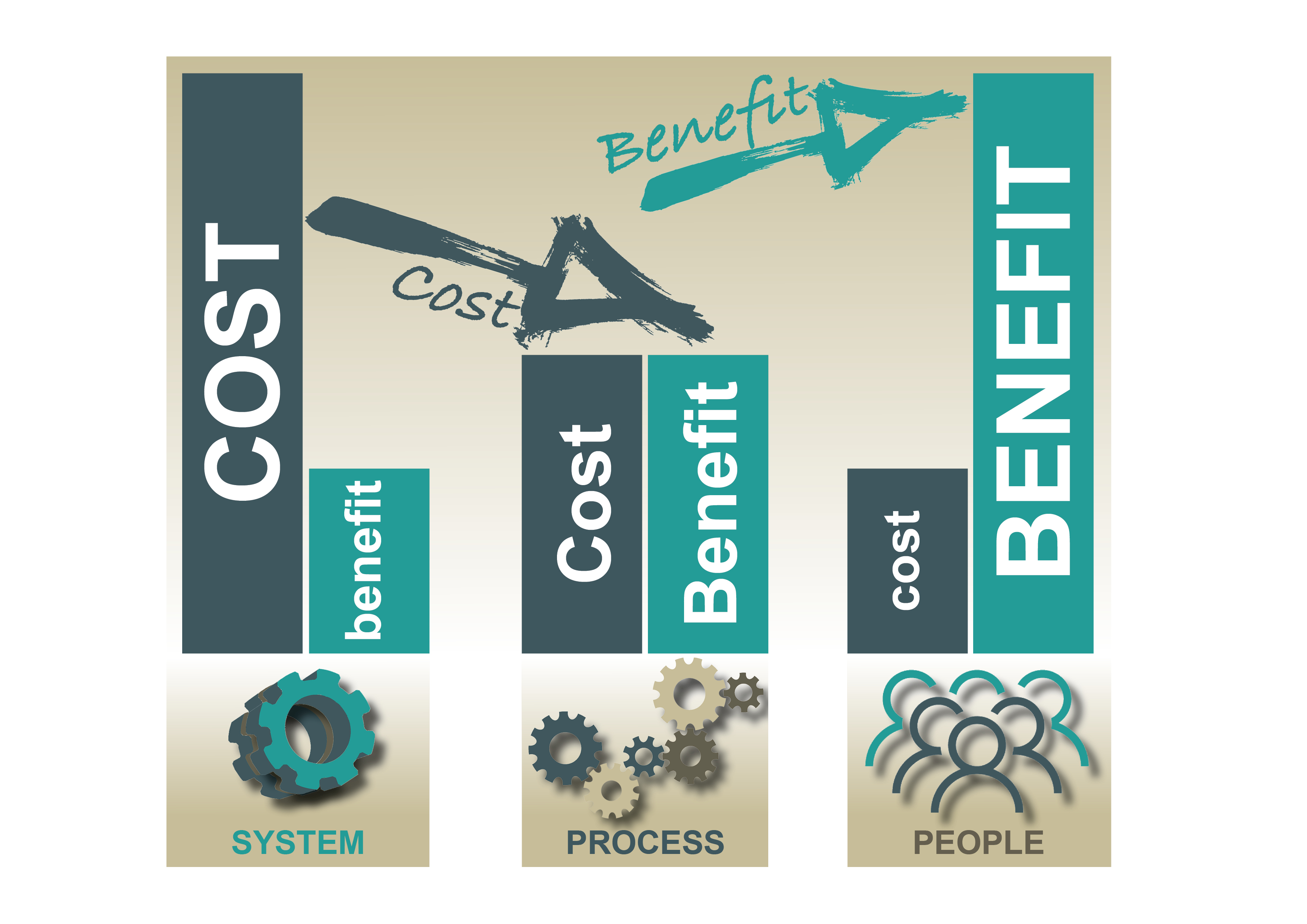

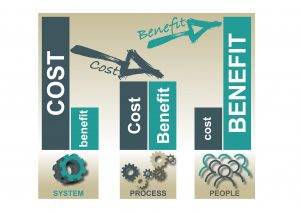

At the beginning most companies recognise that implementing ERP is about transformation and requires behaviour, process and systems change. However as the project develops it often tuns into a systems installation project; this is especially true in the later phases of the project or if the project has suffered delays when enormous pressure mounts to simply go live an stop the financial ‘burn rate’. This will result in simply an automation of the current firefighting environment and will fail to deliver the significant business benefits or achieve excellence. Technology and systems functionality are extremely powerful today and can enable significant improvement but it has to be recognised that the majority of benefits are generated from people.

DMi Cost Benefit

In order to ensure that the benefits are achieved then it is essential that the ERP project remains focused upon transformation and is not allowed to slip into systems installation project. The cut over criteria below should be agreed at the beginning of the project by the Steering Committee (Leadership Team) and then rigorously defended throughout the life of the project, especially in the later phases when the temptation to ‘just go live’ and compromise the criteria will be at its greatest.

Criteria – ‘The 8 point checklist’

- Integrated Business Planning/Sales Operations Planning an IBP

An IBP/S&OP process has been established and is working effectively which addresses medium to long term issues and creates management stability

- Leadership Commitment

All of the Leadership Team have shown commitment to the transformation throughout all phases of the project and continue to do so through demonstrating their own behaviour change.

- System Functionality

The system uses basic standard functionality as described in “MRPII the Standard System” – Daryl Landvater and Chistopher Gray. It is fully integrated or interfaced with other systems enabling ‘one set of numbers’, it has been configured to meet the defined process requirements but bespoke modifications have been kept to a minimum to enable future upgrades.

- Data Quality

All data has been ‘cleaned’ and a process for maintaining and measuring that data has been established. In particular key planning data quality must have been achieved and sustained for at least 3 months prior to cut over.

- Inventory records > 95%

- Process routings > 95%

- Item Master Data > 95%

- Work Centre Data > 95%

- Bills of Material > 98%

In addition there must be no past due purchase, manufacturing or customer (back log) orders in the system, demonstrated capacity is recorded and monitored, customer and supplier master files are accurate.

- Education and Training

100% of people have received effective education to understand the why and best practice and as required systems training to understand the how. 100% because as Brian Clough (Football manager) once said “if they are not interfering with play why are they on the pitch!”

- Accountability

Accountability and ownership for the adoption of the new system, process and behaviour has transferred from the Project Team to Managers and users. This is supported by an established set of aligned KPIs that have been designed to drive the desired behaviour and continuous performance improvement.

- Piloting

All business leaders, managers and users (direct and indirect) have successfully completed pilots that simulated the new operating model (systems, process and behaviour) not just tested the system or where used by the software company as user acceptance testing (ACT). The purpose of piloting is to test and confirm the ‘readiness’ of the organisation to go live.

- Post Cutover

A team of super users and ongoing transformation support has been established to help the organisation deal with post cutover problems and to sustain the ongoing transformation.

If the organisation commits to these 8 cutover criteria then the likelihood of the ERP project being a business transformation rather than a system implementation will be significantly enhanced.