3:01 pm

3:01 pm

DMi White Paper: ERP Systems Functionality Selection Checklist

ERP Systems Functionality Selection Checklist

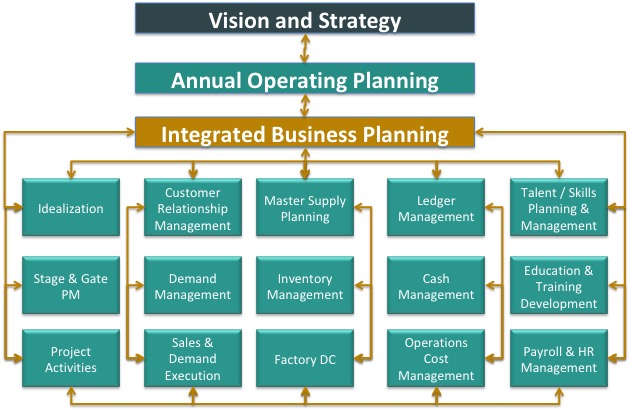

This document is not intended to pick up all of the functionality of a typical ERP system, for example it does not cover areas such as ledgers, CRM, HR or basic purchase orders and stock transactions. Its objective is to act as a checklist for the key planning and control functionality required for best practice ERP during a systems selection process.

IBP

- Aggregation/disaggregation to multiple families

- RCCP at family level using resource profiles and long-term time fences

Demand Planning/Management

- Statistical forecast capability

- Assumption management functionality

- Forecast accuracy KPIs using customer demand not shipments or customer orders

- Multiple views of forecast accuracy e.g. by customer, account manager, sector etc.

- Forecast bias KPIs

- Available to promise functionality based upon the MPS and stock

- Abnormal demand filters

- How is unconsumed forecast and forecast roll handled?

- Customer service KPIs – OTIF against customer demand and customer order (requested and promised)

Master Production Scheduling (Master Supply Planning)

- Types of order status – planned, firm planned (FPO) and released

- Time fence management capability, FPO time fence and released time fence.

- Change management and KPIs within each time zone

- Planning buckets month, week, day, shift, hour

- Action messages types and filters

- Pegging capability to support bottom up re planning

- MPS/MRP calculation net to gross not gross to gross

- RCCP capability at MPS level using resource profiles

- Detailed capacity planning (infinite) using released orders, FPO’s and planned orders using detailed work centre and operational routings and demonstrated capacity

- Full distribution resource planning functionality using DC demand and distribution resource requirements e.g. Logistics, Warehouse space (if required)

- Planning bill functionality

- Does a requirements file exist allowing changes made to manage exception and bottom up re-planning not to be overridden next time MPs/MRP is run?

- MRP run net change and can it be online allowing better scenario planning during the re-planning process

Bills of Material

- Modular BOM functionality

- Pseudo item numbers

- Phantom item numbers correctly used in MRP

- Lot control capability

- Back flushing capability by shop order or routing operation

- BOM maintenance functionality e.g. mass replace, where used

- Change management functionality, discrete effectivity date, use up

- Multiple views of one BOM database – live, manufacturing, planning, development and costed

- Detail work centre and operations routings used by CRP and production scheduling

Vendor Management

- Vendor scheduling functionality, with time fences and the ability to handle multi (duel) sourced items

- Vendor analysis based upon segmentation and cash flow projections

Stock Control

- Cycle counting (Perpetual inventory) functionality, including ‘process control’ cycle counting

- FIFO functionality

- Lot control functionality with traceable capability

- Standard stock control transactions

- Back flushing and KANBAN functionality

- Discrete picklist functionality

Shop Floor Control

- Material availability check prior to shop order release

- Production scheduling based upon routing operations and work centre profiles e.g. move time, Q’s, SHITS, shop calendar

- Production scheduling is based upon standard operation times and set up while MRP is based upon item master lead times. What comparison capability exists to ensure alignment.

- Finite production scheduling functionality

- Planning board capability for communication of production schedule

- Production reporting functionality by order, by operation with option for specific count points

- Full production and material traceability functionality

- Schedule adherence KPIs

Business Information

- What BI tools exist to support KPIs, analysis and the IBP Review Steps.

I hope that this checklist serves as a help during the system selection process. Enjoy the ‘shopping’ but don’t procrastinate.