In today’s competitive business world which has only got more global and challenging over the past few years with the uncertainty of the world trade wars, economic/political stability and Brexit this will only get more intensive over the next 2 -5 years. This is no more so than in the manufacturing and supply chain sector. If the UK is to prosper post Brexit and Europe are to capitalize on the UK market then Integrated Business Planning/S&OP, Supply Chain Optimization, Demand Planning and Management, Product Lifecycle Management and Leadership development will be critical success factors for companies on the future. For any manufacturing or supply chain organisation operational excellence will be crucial for their future success. This will require a clear focus upon transformational change and change management. ‘best in class’ processes and aligned KPIs driving integrated behaviour and cultural change.

Key process areas will include Integrated Business Planning (S&OP), demand Planning and Forecasting, Supply Chain Optimisation, ERP implementation and development along with Leadership development and a balanced scorecard of KPIs and measures.

DM Integration and Dave Manning have supported hundreds of companies on the journey to sustainable excellence in more than 70 countries from global corporations to SME local companies. This support has taken the form of Executive Briefing management engagement, best practice Public and tailored education sessions, specific process design workshops, coaching and consulting sessions and best practice assessment against the DMi Checklist of Business Excellence.

Integrated Business Planning

The IBP/S&OP process is the primary process through which the business is managed and strategy is executed. It is not a meeting or even a series of meetings it is a continuous process throughout the month focused upon the long term, decision making and gaps. The work is done in the process and decisions taken at the Reviews. IBP operates at an aggregate level not detail, it is ‘roughly right not precisely wrong’.

Business success has always depended upon integration. At the highest level the focus of this integration is of people/behaviour, processes and systems all within the overall structure of the organisation. When all four of these circles converge then you are in the ‘sweet spot’ which is where excellence and maximum effectiveness exists.

Integrated Business Excellence Model

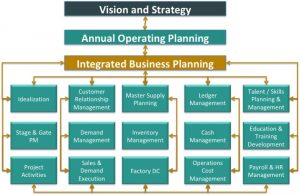

DMi Integrated Business Excellence

This operating model is a totally integrated holistic model that goes from vision and strategy through to detailed execution and from product life cycle/development to customer life cycle and sales execution. It embraces the end to end supply chain and is supported by people development, continuous improvement, data management and reviewed through a balanced set of KPI’s (measures) and CSF’s (critical success factors).

Process Map

DMi Integrated Process Map

This model was once referred to as the ‘plumbing chart’. It shows the detailed processes that are used to operate the business on a day to day basis as well as drive the plans and decisions made through the IBP and strategic planning process. These detailed processes must be fully integrated across the end to end supply chain and be supported by excellent and maintained data. People’s behaviour must also be team focus driven by an aligned balanced score card of KPI’s

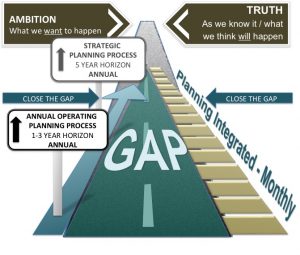

Gap

At the heart of business management is the management of the gap. This gap could be a strategic, financial, product, resource, sales or capability gap. It can also be a negative gap that needs to be closed or a positive gap (growth) that needs to be opened. The top down processes set ambition for the organisation and the bottom up process (IBP) provides visibility of the gaps that require actions and decisions with sufficient horizon for those actions to be taken in a planned approach not a reactive ‘firefighting’ one.

Proven Path

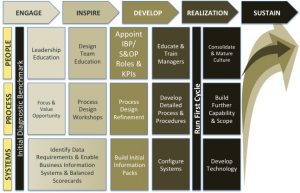

DMi IBP-S&OP Proven Path

The Proven path is effectively a transformational change management process which embraces the three criteria that must simultaneously exits for change to happen and be sustainable:-

- A discontent with the present

- A vision of a created future

- A path of least risk to manage the change

The original proven path was developed by Ollie Wright back in the 60’s and has been developed and evolved through its application in 100’s of successful transformational programmes. At its core are four key principals:-

- Best practice education to create best practice understanding and engagement of ‘why’

- Process and behaviour change not just systems implementation

- Cascade education. The principal of managers teaching their own people

- A series of pilots, not just of the systems but of the processes and behaviours as well which all employees participate in.

The DMi Proven Path can be applied at any transformation programme. It may or may not include the implementation or upgrade of systems or it might be for a specific process such as IBP/S&OP or Demand management and Supply Chain Optimization.